Tire Tips and Tricks

Front and Rear Tire Matching

Remember, correct matching of front and rear tires is important to obtain

optimum performance and handling. Follow the Tire Selection guidelines.

Mount only tires marked “front wheel” on front positions and only

tires marked “rear wheel” on rear positions.

A new front tire with a worn rear tire can cause instability.

Mixing radials, or mixing radials with bias or belted bias tires may adversely

affect handling and stability. Always fit Dunlop Sportmax, Sportmax II D204,

Sportmax touring D205 and Dunlop D207 high-performance radials in pairs. It

should be noted that many factors other than tire incompatibility can affect

the handling of a motorcycle, including the weight and height of the rider,

mixing worn with unworn tires, and the fitment of luggage or fairings. Consult

the motorcycle manufacturer before making modifications from stock.

Maintaining Clearance

Consult the motorcycle manufacturer if you intend to mount sizes other than

indicated in the owner's manual. Remember the tire's physical dimensions are

important. Adequate clearance of fenders, swingarm, etc., must be maintained.

Increasing tire size may require an increase in rim width. When increasing

tire size and/or rim width, rotate wheel and inspect closely for sufficient

clearance.

Tubes

Tubes are a crucial part of the tube-type wheel assembly. They should be treated

with respect. When fitting a new tire on a rim requiring a tube, a new tube

should be fitted at the same time. Old tubes become stretched and if an old

tube is fitted within a new tire, it can crease and fail due to thinning of

the tube rubber. Tubes should be repaired only by an expert. Secure tube valve

assembly to rim with care. Inspect rim band and consult motorcycle dealer

for correct rim band replacement. Always check the size markings on the tube

to assure that the tire size appears on the tube. Do not fit tubes in radial

motorcycle tires, nor fit radials on rims requiring tubes, unless the tubes

bear matching size and radial (R) markings.

Tire Pressures (see also Tire Mounting)

Follow pressure recommendations shown on the Motorcycle Tire Application Guide.

Contact manufacturer if year and model are not shown on the current guide

and the owner's manual does not list pressure settings for your tires. Keep

in mind that hard cornering, passengers, heavy loads and sustained high speeds

will require higher pressures (up to that indicated on the sidewall).

CHECKING TIRE PRESSURES IS THE MOST IMPORTANT TIRE MAINTENANCE FUNCTION YOU CAN PERFORM.

For high-speed, fully loaded or dual-riding touring motorcycle applications, inflate front tires to maximum recommended by vehicle manufacturer for fitment and rear tires to maximum load inflation pressure on sidewall. Rear touring tires must be inflated to a minimum of 36 psi for light to medium loads and 40 psi for dual riding and other loads. Never exceed maximum load indicated on tire sidewall or vehicle capacity load found in owner's manual. Underinflated tires can result in imprecise cornering, higher running temperatures, irregular tread wear at the edge of the contact patch, fatigue cracking, overstressing and eventual failure of the tire carcass. Overinflating tires does not increase load carrying capacity, but will result in a hard ride and accelerated tire wear in the center of the contact patch. Check cold tire pressure frequently with a good quality gauge that holds a reading, and always before extended trips. Loss of pressure may occur due to worn out or badly seated valve cores. Check valve cores. If necessary, tighten for correct seating, or remove and replace them. A metal or hard plastic valve cap with an inner gasket should be used and installed finger tight to protect the valve core from dust, moisture and to help maintain a positive air seal. Repeated loss of inflation pressure may result from undetected tire damage. Visually inspect tires for punctures, cuts, abrasions, cracks, bulges, blisters or knots. It will be necessary to dismount the tire to complete an inspection for internal damage and any need for repair. See the Tire Repair section. Only certain punctures in the tread area may be repaired, and only if no other damage is present. Tires with non-repairable damage must not be used again. Damage caused by impacts, penetrations or continued underinflated/overloaded use is progressive and can result in sudden and complete tire failure and accident. Always seek expert inspection of the dismounted tire following curb, chuckhole or other impacts, evidence of penetration beyond the tire surface, bulges or low pressure. Do not continue riding on such tires. Inspect your tires frequently for damage and always heed warning signs such as vibration, handling instability, rubbing or tire noise that occurs during operation of the motorcycle.

Speed Ratings

S, H, V, and Z ratings where applied are indicative of high-performance capability

based on indoor wheel testing and are not valid for damaged, altered, repaired,

excessively worn, underinflated or overloaded tires. It is not recommend to

use of any tire products in excess of legal speed limits. Consult the owners'

manual for recommended speed rating and do not mix ratings front to rear.

Run-in Period

Replacements for worn, differently patterned or constructed tires will not

react the same. When new tires are fitted, they should not be subjected to

maximum power, abrupt lean-over or hard cornering until a reasonable run-in

distance of approximately 100 miles has been covered. This will permit the

rider to become accustomed to the feel of the new tires or tire combination,

find the edge, and achieve optimum road grip for a range of speeds, acceleration

and handling use. Check and adjust inflation pressure to recommended levels

after tire cools for at least three (3) hours following run-in. Remember,

new tires will have a very different contact patch and lean-over edge. New

tires, mixing a new tire with a worn older tire, and mixing different pattern

combinations require careful ride evaluation.

Wheel Balance

It is essential tire/wheel assemblies be balanced before use and rebalanced

each time the tire is removed or replaced. Unbalanced tire/wheel assemblies

can vibrate at certain speeds, and tire wear will be greatly accelerated.

All street tires should be installed with the yellow balance dot at the valve.

Wheels may be balanced with spoke nipple weights, lead wire or self-adhesive

rim weights. Consult the motorcycle manufacturer for approved wheel weights.It

is not recommend that you use dry or liquid balancers/sealers and will not

warrant tires into which these materials have been injected. Tire and wheel

assembly balance must be checked with a balance stand or computer wheel balancer.

Replace immediately any broken spokes and tighten any loose ones. Broken spokes

transfer additional tension to adjoining spokes, creating the potential for

further spoke failures. After tightening or replacing spokes, be sure that

the wheel rims run true. Inspect the rim, rim band and tube, and replace any

of these components if they are damaged before refitting the tire. Both broken

and loose spokes may cause wheel wobble, thus accelerating tire wear, and

could cause instability.

Tube-Type Rims

Note: Not all cast wheels, whether aluminum or magnesium, are suitable for

tubeless tire fitment. Mount tires as tubeless only when the wheel manufacturer

recommends it. Some spokeless rims require tubes. With a tube inserted,

a tubeless tire may be fitted to a tube-type wheel. Exception: Tier manufacturers

do not recommend fitment of non-radial tubes in radial tires. Ensure that

tube markings match radial tire markings before fitting to rims requiring

tubes.

The treatment that tires receive during extended periods of inactivity may

directly affect their mileage and performance.

Tires stored in direct sunlight for long periods of time will harden and age

more quickly than those kept in a dark or dimly lit area.

Prolonged contact with oil or gasoline causes contamination of the rubber

compound, making the tire unsuitable for use. Wipe off any oil or gasoline

immediately with a clean rag. Do not use any tire that has been exposed to

oil, gasoline, corrosives or non-rubber compatible liquids.

Safety note: 22 psi front and 22 psi rear are minimum pressures for dual-sport

highway use. Pressures for dual-sport use must be increased to pressures specified

by the motorcycle manufacturer for highway use.

It is recommended that only permanent repairs performed from

the inside of the tire, using a combination patch/plug method. Never attempt

a repair from the outside, or inject a sealant, or simply use an innertube,

a patch or a plug as a substitute for a proper repair. Only a qualified tire

repair shop or motorcycle tire dealer should perform repairs. Inspection of

the tire and adequacy of repair becomes the responsibility of the person actually

performing the repair and manufacturers do not warrant the results of a repair

in any way. Combination patch/plug repair kits for use by the repair shop

or dealer are available with accompanying instructions from companies such

as:

Remarco Inc.

200 Paris Ave.

Northvale, NJ 07647

(201) 768-8100

Technical Rubber Co.

P.O. Box 486

Johnstown, OH 43031

(740) 967-9015

Tip-Top/Moto Combi Kit

Tech Uni-Seal® Repair Kit (Also has been marketed by Honda,

Kawasaki, and Yamaha with their own part numbers.)

NOTE: There may be suitable repair kits and materials provided by manufacturers

other than those listed above.

Before any repair should be attempted, however, a tire must be removed from the wheel and thoroughly inspected. The following are minimum guidelines for the repairer:

Tires should not be repaired if any of the following conditions

exist:

A tire has been previously injected with a sealant/balancer.

The puncture is larger than 6mm (1/4") in diameter.

The puncture is not perpendicular to the carcass.

The puncture is in the tire sidewall.

Separation of plies, tread separation, separation of any other components.

Cut or broken ply cords.

Broken or damaged bead wires.

Cut or damaged chafers (bead area).

Deterioration of the carcass inside the tire due to "run flat" or

underinflation.

Cracks or other damage to the integrity of the inner liner.

Excessive wear - tire should have at least 1/32 of an inch of tread depth,

excluding tread wear indicators.

Cracks in sidewall or tread.

Impact breaks, cuts, snags or gouges that penetrate the surface.

NOTE: There should be no more than one repair in any quarter of the

tire and no more than two repairs per tire.

The wheel itself must be in good condition. Any cracked or bent wheel, however

slightly, may allow the loss of air and cause subsequent deflation of the

tire.

Following repair, the valve assembly should be replaced and the tire/wheel

rebalanced.

Speed should not exceed 50 mph for the first 24 hours after tire repair and

the repaired tire should never be used at speeds over 80 mph. The repairer

is solely responsible for instructing the motorcyclist as to the restrictions

to be placed on tire use following repair.

In summary, NO form of temporary repair should be attempted. Motorcycle tire

repairs leave no room for error and any doubt as to inspection or adequacy

of repair should be resolved by discarding the tire.

Be sure to consult our Motorcycle Tire Limited Warranty, Care

and Maintenance brochure for additional information regarding the use of your

tires. Seek a qualified motorcycle tire repair center for more details. NEVER

ATTEMPT TO REPAIR A DAMAGED TIRE WITHOUT THE AIDE OF AN EXPERIENCED TIRE MECHANIC.

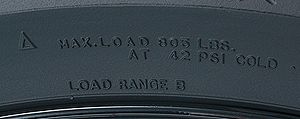

Tires offering different load-carrying capacities are available. Consider

carefully the weight of the motorcycle, the weight of any optional equipment

and whether it will carry passengers. Remember, the load- carrying capability

of the tires is also reduced by underinflation. It is possible to overload

a tire even though it is the size specified by the motorcycle manufacturer.

Maximum loads and corresponding pressures are indicated on the sidewall of

all street tires. Never exceed the accessory restrictions and vehicle load

capacity found in the motorcycle owner's manual, or the maximum load molded

on the tire sidewall. Before a trip, be sure to determine the total weight

of luggage, equipment, and rider(s) to be added to the motorcycle. Trailers

may contribute to motorcycle instability, grossly exaggerated tire

stresses and overload. Such stresses and overload can cause irreversible damage

resulting in sudden tire failure and accident. Manufacturers do not recommend

the use of trailers, nor warrants tires used on motorcycles fitted with trailers.

Sidecars should not be fitted unless approved by the motorcycle manufacturer.

Consult the tire manufacturer Technical Data Chart or the manufacturer to

ensure that the tires you select are correct for the rims. Correct rim width

may be crucial to handling and stability. A tire that is installed on a rim

wider than recommended will have a flattened profile, and a rider may easily

reach the edge of the tread during cornering. A narrow rim will alter the

tire profile, concentrating tire wear in a very small area during cornering,

with a smaller contact patch during braking. Remember: Tire clearances are

important. Fitment to Harley-Davidson 18-inch and 19-inch CM contour rims

may result in slippage or air loss. Harley-Davidson 18-inch and 19-inch CM

contour rims are not compatible with Dunlop tires. Consult Dunlop if in doubt

and before fitting tires to pre-1980 Harley-Davidson motorcycles.

Street tires have yellow balance dots in the bead or sidewall area to indicate

the lightest point of the tire. Street tires should be installed with these

balance dots at the valve. Street tires also have arrows on the sidewall,

which indicate the correct direction of rotation. Positioning of balance marks

and inclusion of directional arrows are not universal among motorcycle tire

manufacturers.

Excessively worn tires are more susceptible to penetrations. Always remove

tires from service before they reach the tread wear indicator bars (1/32 of

an inch tread pattern depth remaining). Worn/unworn tire combinations and

worn tires used in wet conditions can result in deteriorated handling.

Never put a tire in use that has been subjected to on-the-motorcycle dynamometer

engine testing. This severe use of the tire may result in tread compound degradation

and subsequent failure.

Some punctures in motorcycle tires may be repaired. Most tire manufacturers

recommend only permanent plug-patch repairs of small (maximum 1/4-inch diameter)

tread area punctures from within the dismounted tire by a qualified tire repair

shop or motorcycle dealer. Never perform an exterior repair and never use

an inner tube as a substitute for a proper repair. Speed should not exceed

50 mph for the first 24 hours after repair and the repaired tire should never

be used over 75 mph. Check inflation pressure after tire cools for at least

three (3) hours following run-in, or sooner if air loss is suspected. No form

of temporary repair should be attempted because secondary damage caused by

a penetrating object may not be detected and tire or tube deflation may occur

at a later date. Most manufacturers do not recommend the use of liquid sealants.

These are a form of temporary repair, and they may adversely affect ply material

and mask secondary damage caused by a penetrating object. Reliance upon sealants

can result in sudden tire failure and accident.

All tire manufacturers strongly recommend regular inspection of the motorcycle

generally, and of wheels in particular, because tire mileage and performance

are adversely affected by a poorly maintained vehicle. Take your motorcycles

in to the motorcycle dealer for regular maintenance checks, inclusive of tire

inspections. Maintain suspension settings in strict compliance with the vehicle

owner's manual. Improperly maintained components and incorrect or unbalanced

front fork pressures will affect stability. Low suspension pressure will generate

excessive tire stresses.

Be sure to align the wheels each time the rear wheel is removed or the chain

or belt is adjusted. Each revolution of an incorrectly aligned wheel can scuff

off tread rubber, reduce tire mileage, and impair steering and cornering.

Bent wheel rims and bent or cracked cast wheels should be replaced immediately.

Bent rims may cause wheel wobble, bead unseating and, in the case of tubeless

tires, gradual air loss. Sudden wheel failure may result from the use of cracked

cast wheels. Be aware of these conditions and their consequences.

Use a mild soap solution to clean sidewalls, white striping or lettering,

and rinse off with plain water. Never apply any other material, cleaners or

dressings, to enhance sidewall appearance. These may degrade rubber and remove

inherent ozone cracking/weather checking resistance.

Try to avoid frequent and varied extremes of temperature during storage. Do

not keep tires next to radiators or sources of heat. Tires subjected to these

conditions will age more quickly than those stored in a cool, constant environment.

Do not store tires where electric motors are present. The high concentration

of ozone will accelerate tire aging.

Danger: Only specially trained persons should mount tires. Improper mounting

can cause tire explosion and serious injury.

Follow these mounting precautions:

Wear approved eye protection.

Clean and lubricate beads and rim.

Centralize rim band and tube to prevent pinching if tube-type rim.

*Note directional arrows on sidewall where applicable.

Lock assembly on mounting machine or place in safety cage before inflating

to seat beads.

Set air hose relief valve at 40 psi.

Use extension gauge and hose with clip-on air chuck. Stand back with no part

of your body within the perimeter of the assembled tire and rim.

Inflate with core in valve stem.

Never inflate above 40 psi to seat beads.*

Spin wheel to check bead seating and alignment.

*If the beads do not seat by 40 psi, deflate and repeat above procedures.

Never use a volatile substance or rubber "donut" to aid bead seating.

If the tire is a tube-type, deflate and reinflate after seating to prevent

tube wrinkles.

For 15-inch motorcycle replacement tires, never mount on a 15-inch diameter

passenger car tire rim. Mount only on a 15 M/C motorcycle rim. These passenger

car and motorcycle rims actually differ in diameter.

Never mount passenger car tires on motorcycle rims.

D402 PT bead lock tires may only be mounted on matching Harley-Davidson FXRP,

FLHTP or FLHP rims. Consult your owner's manual and see special tread label

mounting instructions.

Air pressure: Always maintain the recommended tire pressure for the type of

terrain on which the motorcycle is being ridden; check the owner's manual.

Underinflated tires may cause wheel damage when ridden in rocky, rough terrain

and allow the motorcycle to squirm or wander on smooth, hard terrains. Overinflation

may damage the tires and cause an unnecessarily harsh ride. To accurately

measure tire pressure, use a standard tire pressure gauge. Condition: Check

for cuts and gouges that may cause air leakage. Also check the tires for missing

knobs and excessively worn tread. Wheels: To avoid loss of control or injury,

make sure axle nuts are tight and secured. Grasp each tire at the front and

rear and try to rock it on its axle to detect worn-out bearings or loose nuts.

There should be no free play or slip as you rock the wheel. Inspect wheels

for broken or loose spokes and for cracks on the hub or rim.

Many manufacturers continue to be concerned about the lack of attention paid

by many cyclists to proper use and maintenance of their tires, particularly

when fitted to motorcycles intended for touring. Technical personnel have

attended touring rallies all over North America to collect vital data and

give instructional seminars.

What we have observed at these rallies alarms us; many touring riders are not following proper tire maintenance procedures. The requirements for proper tire usage are not complicated, but they do require consistent attention. Owners and operators of motorcycles should closely monitor vehicle loadings to insure they are within the maximum loads and corresponding inflation pressures for their tires. This basic load and pressure information is clearly stamped on the tire sidewalls. The tire does not support the load-the air pressure does. The manufacturer's ratings for the maximum load and inflation pressure are critical tire design elements. If not observed, the handling and performance of your motorcycle will be greatly affected.

We have checked inflation pressures at several touring rallies and found a high percentage of rear tires to be underinflated. In addition, weight checks of the rear axles of these motorcycles indicated a number of tires were loaded beyond maximum capacity. Our inspections have not been limited to those cycles fitted with Dunlop tires; the situation exists for all brands of tires. Regardless of the make of tire, this is a serious problem. Riders of motorcycles with significantly underinflated and overloaded tires will experience handling and steering difficulty. In addition, this abuse will result in disappointing premature tire wear and may cause catastrophic tire failure.

The addition of accessories, cargo, and dual riding to touring motorcycles aggravates the problems of overloading and underinflation. The excessive flexing that results from underinflation or overload causes buildup of internal heat, fatigue cracking and eventual carcass breakup resulting in complete failure. A consequence of such failure may be an accident with serious personal injury or death. The appearance of stress cracks in the tread grooves is one indicator of overload and/or underinflation. If you find evidence of tread groove cracking, you should remove and replace the tire immediately. This damage is permanent and non-repairable.

Our inspection of tires of various style and manufacture at rallies and our subsequent testing have confirmed that underinflation (and/or excessive load) causes tread groove cracking and can result in more serious damage within the tire body. Uneven wear may also accompany underinflated use. Failure to heed these visual warnings can result in tire failure or blowout.

The use of trailers can also contribute to tire damage and touring motorcycle instability. Although most motorcycle manufacturers recommend against their use, a percentage of the motorcycles we have inspected were so equipped. The trailer tongue weight added to an already heavily laden motorcycle can fail a rear tire. The percentage of overloaded motorcycle rear tires found during our inspection would have been higher if trailer tongue weight had been considered. The forces of rapid acceleration and deceleration may also multiply the effects of trailer tongue weight.

To get the maximum safe use out of your tires and maximum touring

enjoyment you should:

Properly maintain all aspects of your vehicle in accordance with manufacturer's

recommendations. Read and reread your motorcycle owner's manual.

Never exceed the loading and accessories restrictions found in your motorcycle

owner's manual, or the maximum load displayed on the tire sidewalls. Know

your loaded vehicle weight!

Check air pressure at frequent, regular intervals, particularly just before

and during long trips. Always use an accurate tire gauge* and check pressures

only when the tires are cold (i.e., wait one hour after running). We have

found many cheap gauges to be off more than 5 psi, so be sure to use a top

quality gauge and preferably one that retains the pressure reading until reset!

Inspect your tires as often as possible. Look for irregular wear, any signs

of cracking in the sidewalls and tread, blisters, knots, cuts or punctures.

Immediately remove and replace damaged tires.

If in doubt, ask your motorcycle tire dealer to check your loading, inflation

and tires. Remember, your tires stand between you and a serious accident.

For touring motorcycle loading,

follow these general guidelines:

Light loads-single rider with some luggage (up to 200 lb. total)-minimum tire

pressure of 32 psi front and 36 psi rear must be maintained.

Heavier loads-dual riding and/or luggage (from 200 lb. total up to maximum

motorcycle capacity stated in the owner's manual)-pressure of 36 psi front

and 40 psi rear must be maintained.

Please Note:

For any dual riding or fully loaded use, 40

psi must be maintained in all rear tires fitted to touring motorcycles.

In addition to following these recommendations, notice what your tires are telling you while you're riding. If your steering response is slow or mushy, or if cornering and braking response is heavy, there's a good chance your tires are underinflated. Vibration or wobble may signal that actual tire damage has occurred and failure is imminent!

If you conscientiously follow our recommendations, you will

enjoy better, longer, and safer tire performance and many, many miles of touring

pleasure.

Wednesday, June 18, 2014 22:17